Introduction

Bottle display screen printing is a top-notch manner to feature emblems, layout and labels on bottles. Many industries use this technique to make their products higher and more expert. From craft beer groups to cosmetic manufacturers, agencies use bottle monitors and print machines to without delay press glass, plastic and steel bottles.

In this newsletter, we will discuss various bottle screen printing machine applications. We will also explain why they are useful for different industries.Learn more about Once-Tech and its advanced printing solutions!

What is Bottle Screen Printing?

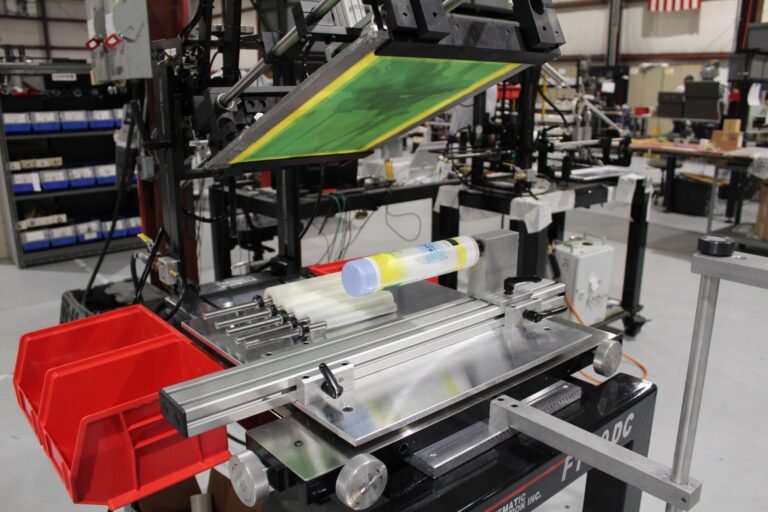

Bottle screen printing is a way of printing designs without delay on bottles. Instead of using the label, the design is printed with ink. This makes prints longer and looks more professional.

A bottle print system helps you print on curved surfaces, including glass and plastic bottles. These machines use unique displays and ink to make excessive first-class prints.

Benefits of Bottle Screen Printing Machines

1. Durable Prints

The printed design does not peel as labels. The ink is robust and lasts in the bottle for a long term.

- Professional shape

Direct stress bottles look more excellent, elegant, and high first-rate. They assist corporations in creating a robust emblem image.

- Waterproof and heat resistant

Unlike the paper label, published designs aren’t damaged through water or heat.

4. Working with distinct components

These machines can press glass, plastic, metal and ceramic bottles.

- Saves money in a long time

Removes the requirement for direct printing paper labels on bottles. It reduces costs in the long term.

- Fast manufacturing

Modern bottle screen printing machines work speedily so that businesses can print numerous bottles in a short time.

- Environmentally friendly

Since there are no paper labels, this approach reduces waste and enables it inside the surroundings.

- High excellent ink alternatives

Many bottle display screen printing machines use UV ink. This ink dries quickly and does now not fade soon.

- Adaptable layout

Companies can print unique people, styles and training in many colours. This allows the creation of brands inside the marketplace.

- Scratches and chemically resistant

Printed bottles aren’t without problems scratched. Ink additionally opposes damage from chemical substances.

Industries That Use Bottle Screen Printing

1. Craft Beer and Beverage Industry

Many artisans use screen printing for their bottles. This enables them to stand on the store shelves. The published layout no longer fades, even if bottles are saved in ice or water.

Juice, tender beverages and wine corporations also use this print approach for their bottles.

- Cosmetic enterprise

Many cosmetic brands print directly on bottles to provide a primary-magic appearance. Products such as perfumes, shampoos, and lotions often have display-prompted designs.

- Pharmaceutical industry

The bottles of the cloth require a clear and durable label. Screen printing ensures that the textual content does not fade over time.

- The meals industry

Sauce, oil, and other liquid meal products frequently come in bottles. Printed designs make those bottles more appealing and informative.

- Chemical enterprise

Chemical products require a clear label that does not fade. Printed bottles assist in making sure that vast warnings and instructions are displayed.

- Luxury and style marks

High-cease marks use display screen printing on perfumes and pores and skin care bottles. This makes their merchandise fashionable and top-rate.

- The sports and health industry

Sports beverages and health offers regularly use display screen printing. This gives bottles a unique and expert appearance.

How to Choose the Right Bottle Screen Printing Machine

When buying a bottle display screen print system, do not forget the following factors:

- Bottom

Check if the machine can print in the form of bottles you operate, together with glass, plastic or steel.

- Writing speed

If you want to print a couple of bottles, choose a fast print-pace device.

- Ink type

Ensure the device supports excessive fine, durable ink to close in the long term.

- Uses ease of use

If you are new to print, choose a device that is straightforward and clean to operate.

- Cost

Compare extraordinary fashions and choose one which suits the price range.

- Durability

A sturdy and dependable device will close for a long time and require less restoration.

- Print size and versatility

Some machines allow printing the scale of various bottles. It is beneficial if you work with different kinds of bottles.

- Automation degree

Completely automated machines paintings speedy, at the same time as semi-automated human beings are reasonably priced. Choose the proper type primarily based on your desires.

- After -Sales Support

Check if the producer presents excellent customer support and machine preservation services.

Future of Bottle Screen Printing

Demand for excessive first-class printing increases. In the future, you will be even better at bottle display printing machines. We can expect:

Fast printing speed

More environmentally friendly ink

Advanced printing technology for exact design

Intelligent machines with automation facilities

AI-operated colour match for proper printing

When the brands search for new ways to face out, bottle display printing will continue to boom.

DTFPRINTY: High-Quality, Fast, and Easy Printing Solutions!

Conclusion

Bottle display printing machines are beneficial for lots of industries. They help companies create robust and permanent brands. From craft beer to cosmetics, many organizations use these machines to print stunning designs on the bottles.

These machines offer durability, an expert form and price savings. If you are a business proprietor selling bottle products, it’s a smart alternative to spending money on a bottle display screen printing machine.

With the proper system, you could create eye-catching and long-lasting designs that attract more clients and boost your commercial enterprise. As the generation improves, you will continue to print bottle screening to provide more benefits for one-of-a-kind industries.